Glass Matters

Better known as glass, silica is a versatile material used in myriad industrial processes, from catalysis and filtration, to chromatography and nanofabrication. Yet despite its ubiquity in labs and cleanrooms, surprisingly little is known about silica’s surface interactions with water at a molecular level.

“The way water interacts with a surface affects many processes,” said Songi Han, a UC Santa Barbara professor of chemistry and author on a recent paper in the Proceedings of the National Academy of Sciences. In many cases, she explained, scientists and engineers intuit the potential interactions between silica and water and design equipment, experiments and processes based on empirical evidence. But a mechanistic understanding of how the chemical topology of silica surfaces alter the structure of water at the surface could lead to a rationale design of these processes.

For many people, glass is glass, and brings to mind the clear, hard, smooth, homogenous-looking material that we use for windows or tableware. However, on a deeper level what we call “glass” is actually a more complex material that can contain different chemical properties with wide-ranging distributions.

“Glass is a material we’re all familiar with, but what many people probably don’t know is that it is what we would call a chemically heterogeneous surface,” said graduate student researcher Alex Schrader, lead author of the PNAS paper.

There are two different types of chemical groups that comprise glass surfaces, he said: silanol (SiOH) groups that are generally hydrophilic (water-loving), or siloxane (SiOHSi) groups that are typically water-repellant. “What we show,” Shrader said, “is that the way that you arrange these two types of chemistries on the surface greatly impacts how water interacts with the surface, which, in turn, impacts physical observable phenomena, like how water spreads on a glass.”

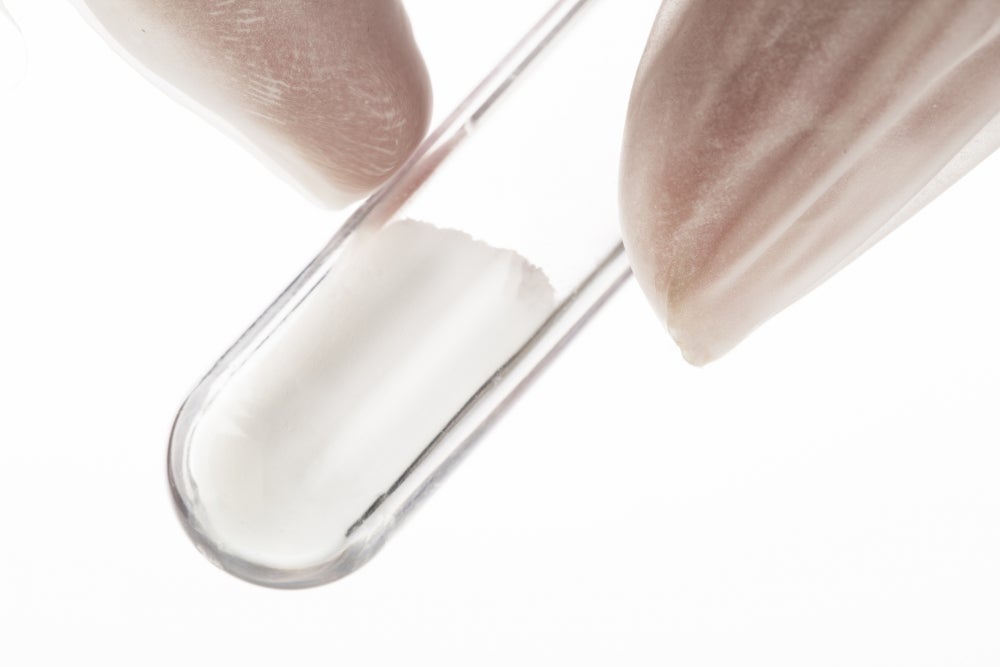

In certain processes such as catalysis, for instance, silica (aka silicon dioxide or SiO2) in the form of a whitish powder is used as a support — the catalyst is attached to the powder grains, which in turn carry it into the process. While silica does not participate directly in the catalysis, the surface molecular composition of the silica grains can influence its effectiveness if the chemical group is predominantly hydrophilic or hydrophobic. The researchers found that if the silica tends to have hydrophilic silanol groups on its surface, it attracts water molecules, in effect forming a “soft barrier” of water molecules that reactants would have to overcome to somehow penetrate to proceed with the desired process or reaction.

“There are always dynamics and the water molecules must exchange their positions, and so that’s why it’s complicated,” said UCSB chemical engineering professor Jacob Israelachvili, whose surface forces apparatus (SFA) measured interaction forces between silica surfaces across water. “You have to break some bond in order for this other bond to form. And that can take time.”

It’s not just the mere presence of the silanol groups that can affect water adhesion to silica surfaces. The researchers were puzzled by a nonlinear drop in surface water diffusivity — as measured by the Overhauser dynamic nuclear polarization apparatus in the Han lab — as the chemical composition of the silica surface moved from hydrophobic to hydrophilic. That mystery was subsequently solved by UCSB chemical engineering professor Scott Shell and his graduate student Jacob Monroe, whose computer simulations revealed the relative arrangement of silanol and siloxane groups on the surface also had an influence on water adhesion.

“If you have the same fraction of water-liking groups and water-disliking groups, by just rearranging them spatially, you can vary water mobility significantly,” Han said.

Catalyst-driven processes are not the only thing that can be improved with a molecular understanding of silica-water adhesion. Filtration and chromatography may also be improved.

“It’s also important in cleanroom procedures, nanofabrication and microprocessor formation,” said Schrader, who pointed out that microprocessors are fabricated on silicon wafer substrates with a thin layer of glass, upon which circuits are laid. “It’s important to understand how the actual surface of the silicon wafer looks on a chemical level and how these different metal layers that they deposit on it stick to it and how they appear.”