A Granular Understanding

Honey is already a pretty thick liquid, but let it begin to crystalize and it can become downright clumpy. The sugar crystals in suspension seem to increase its viscosity. This phenomenon occurs throughout the natural and constructed world: From mudflows to paint, suspensions of particles tend to behave like viscous fluids.

Engineers use this to their advantage by modeling the macroscopic properties of a suspension based on the size and concentration of its particles. However, this approximation breaks down at a certain scale. UC Santa Barbara’s Virgile Thiévenaz and Alban Sauret sought to determine when and how.

They discovered that particles don’t spread out evenly once a suspension drops below a certain length scale, such as when the fluid pinches in to form the neck of a droplet. Eventually, there will be a thin region without any particles that behaves like a pure liquid. The findings, published in the Proceedings of the National Academy of Sciences, highlight the limit of approximations and have many potential applications in industrial settings.

Viscosity quantifies the internal friction between layers of a fluid. In a viscous liquid, one layer exerts more drag on its neighbor, producing a thicker fluid that is more resistant to deformation and flow. Particles in a suspension behave in a similar manner. A particle is more likely to move when its neighbors move, which increases the fluid’s effective viscosity. Higher concentrations bring particles closer together, strengthening the effect. “So as long as you look at the suspension from far away, it’s just a more viscous liquid,” explained Thiévenaz, a postdoctoral researcher in the mechanical engineering department.

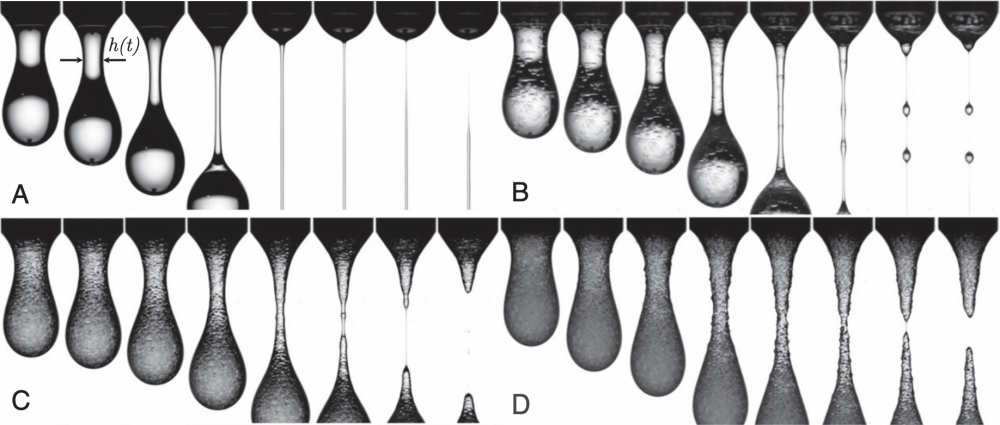

In droplet experiments, Thiévenaz and Sauret observed that suspensions will stretch like a viscous liquid down to a certain thickness, after which it becomes possible to pull the particles away from each other. This creates regions with varying concentrations that behave differently. Eventually, a region won’t contain any particles and will act like a pure fluid. After this, the effective viscosity simplifies to that of the pure liquid.

A droplet of silicone oil pinches of from fluids with different concentrations of 140 µm particles: (A) is pure liquid, (B) is 2% concentration, (C) is 20%, and (D) is 50%.

Photo Credit: THIÉVENAZ AND SAURET

Engineers have compiled a lot of data to calibrate the effective viscosity of suspensions with particle size and concentration at large scales. Thiévenaz and Sauret’s challenge was to figure out at what scale the approximations classically used to model suspensions began to unravel.

With more experimentation, the authors determined that this threshold also varies with particle size and concentration. A suspension will transition from acting like a viscous fluid to behaving more like a heterogeneous mixture at scales on par with the size of the particles.

Interestingly, smaller particles seem to have a proportionately stronger effect. “Relative to the particle size, the threshold is much larger for small particles at a given concentration,” said Sauret, an assistant professor of mechanical engineering.

For instance, a suspension with a 30% concentration of 140 micrometer particles may behave smoothly down to scales of 600µm, or about four times the particles’ diameter. But a suspension with 20µm particles at the same concentration may display this effect down to 250µm: a smaller scale overall, but more than 12 times the particles’ diameter.

Predicting the behavior of a suspension has major applications in manufacturing. A process may require manipulating films or creating tiny droplets, and technicians need to be able to predict the properties of these systems. For dip-coated parts, properly manipulating the particles in a film can be the difference between a finished product and an absolute mess, Sauret explained.

Spray coating provides an even clearer illustration of this phenomenon. A pure liquid, like a varnish, will behave differently than a suspension, like paint, when spray coating a product. When compared to a pure liquid with the same effective viscosity, a suspension will break up earlier with fewer, larger droplets. The researchers’ next task is determining how the number and size of droplets depends on parameters like speed, particle concentration and particle size.

Approximating suspensions as viscous liquids works well, but only at certain scales. “At some point that’s going to fail,” Sauret said. “And we need to be able to say, ‘at this point you cannot use this approach, and instead you need to use a different method.”