Custom-Built to Ready-Made

Information technology continues to progress at a rapid pace. However, the growing demands of data centers have pushed electrical input-output systems to their physical limit, which has created a bottleneck. Maintaining this growth will require a shift in how we built computers. The future is optical.

Over the last decade, photonics has provided a solution to the chip-to-chip bandwidth problem in the electronic world by increasing the link distance between servers with higher bandwidth, far less energy and lower latency compared to electrical interconnects.

One element of this revolution, silicon photonics, was advanced 15 years ago by the demonstration from UC Santa Barbara and Intel of a silicon laser technology. This has since triggered an explosion of this field. Intel is now delivering millions of silicon photonic transceivers for data centers all around the world.

A new discovery in silicon photonics by a collaboration of UC Santa Barbara, Caltech and the Swiss Federal Institute of Technology Lausanne (EPFL) reveals another revolution in this field. The group managed to simplify and condense a complex optical system onto a single silicon photonic chip. The achievement, featured in Nature, significantly lowers the cost of production and allows for easy integration with traditional, silicon chip production.

“The entire internet is driven by photonics now,” said John Bowers, who holds the Fred Kavli Chair in Nanotechnology at UC Santa Barbara, directs the campus’s Institute for Energy Efficiency and led the collaborative research effort.

Despite the great success of photonics in the Internet backbone, challenges still exist. The explosion of data traffic puts a growing requirement on the data rate each individual silicon photonic chip can handle. Using multicolor laser light to transmit information is the most efficient way to address this demand. The more laser colors, the more information that can be carried.

However, this poses a problem for integrated lasers, which can generate only one color of laser light at a time. “You might literally need 50 or more lasers in that chip for that purpose” said Bowers. And using 50 lasers has a number of drawbacks. It’s expensive, and rather inefficient in terms of power. What’s more, the frequency of light each laser produces can fluctuate slightly due to noise and heat. With multiple lasers, the frequencies can even drift into each other, much like early radio stations did.

A technology called “optical frequency combs” provide a promising solution to address this problem. It refers to a collection of equally spaced frequencies of laser light. Plotting the frequencies reveals spikes and dips that resemble a hair comb —hence the name. However, generating combs required bulky, expensive equipment. Using an integrated photonics approach, Bowers’ team has demonstrated the smallest comb generator in the world, which resolves all of these problems.

The configuration of the system is rather simple, consisting of a commercially distributed feedback laser and a silicon nitride photonic chip. “What we have is a source that generates all these colors out of one laser and one chip. That’s what’s significant about this,” Bowers said.

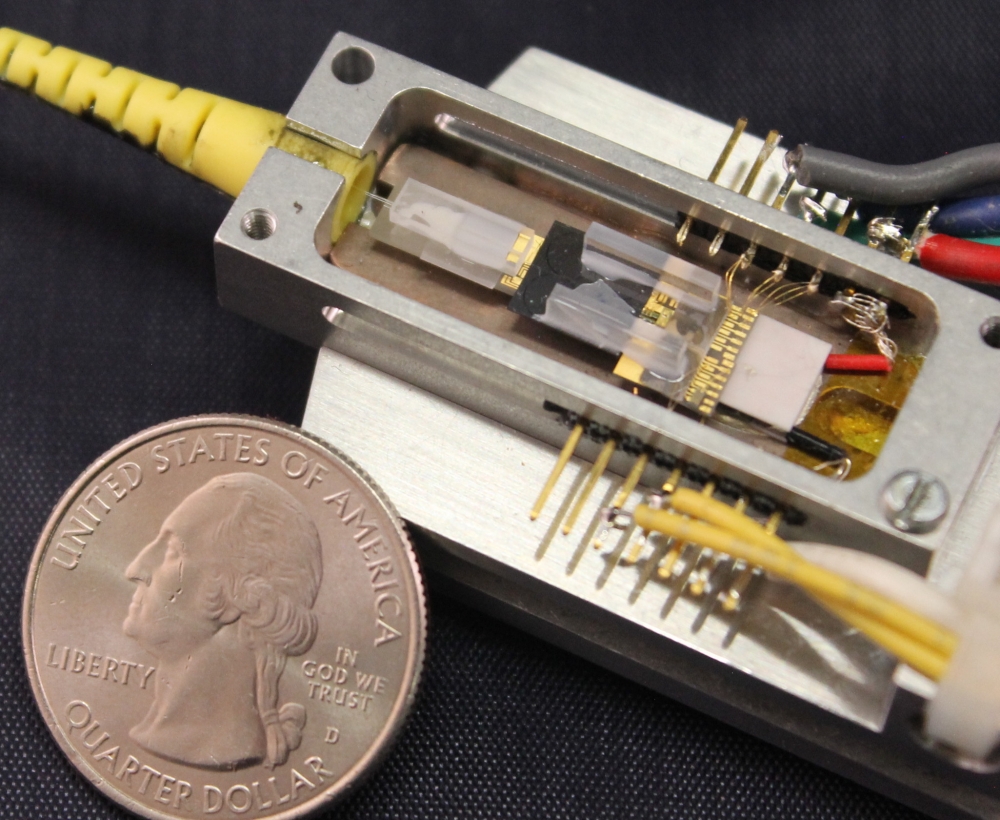

The internal workings of the turnkey soliton microcomb chip, with quarter for scale.

Photo Credit: Lin Chang

The simple structure leads to a significant reduction of scale, power and cost. The whole setup now fits in a package smaller than a match box, whose overall price and power consumption are smaller than previous systems.

What’s more, the new technology is also much more convenient to operate. Previously, generating a stable comb had been a tricky endeavor. Researchers had to modulate the frequency and adjust power just right to produce a coherent comb state, called soliton. That process was not guaranteed to generate such state every time. “The new approach makes the process as easy as switching on a room light,” said coauthor Kerry Vahala, a professor of applied physics and information science and technology at Caltech.

“What is remarkable about the result is the reproducibility with which frequency combs can be generated on demand,” added Tobias J. Kippenberg, professor of physics at EPFL who provided the low loss silicon nitride photonics chips, a technology already commercialized via LIGENTEC. “This process used to require elaborate control in the past”.

The magic behind all these improvements lies in an interesting physical phenomenon. When the pump laser and resonator are integrated, the interaction between them forms a highly coupled system that is self-injection locking and simultaneously generates “solitons”, pulses that circulate indefinitely inside the resonator and give rise to optical frequency combs. “Such interaction is the key to directly generating the comb and operating it in the soliton state” explained coauthor Lin Chang, a postdoctoral researcher in Bowers’ lab.

This new technology will have a big impact on photonics. In addition to addressing the demands of multicolor light sources in communication related products, it also opens up a lot of new opportunities in many applications. One example is optical clocks, which provide the most accurate time standard in the world and have many uses — from navigation in daily life to measurements of physical constants.

“Optical clocks used to be large, heavy and expensive,” Bowers noted, “and there are only a few in the world. With integrated photonics, we can make something that could fit in a wristwatch, and you could afford it. Low noise integrated optical microcombs will enable a new generation of optical clocks, communications and sensors. We should see more compact, more sensitive GPS receivers coming out of this approach.”

All in all, the future looks bright for photonics. “It is the key step to transfer the frequency comb technology from the laboratory to the real world.” Bowers said. “It will change photonics and our daily lives.”

This research was a collaboration of UC Santa Barbara, the California Institute of Technology and the Swiss Federal Institute of Technology Lausanne (EPFL). The project was funded by DARPA’s Direct On-Chip Digital Optical Synthesizer (DODOS) program, which demonstrated optical synthesizers using photonic integrated circuits.