Leveling Up

Maintaining things in working order requires constantly improving processes behind the scene. As the red queen in Lewis Carroll’s “Through the Looking Glass” says, “You see, it takes all the running you can do, to keep in the same place. If you want to get somewhere else, you must run at least twice as fast as that!”

Now a group of UC Santa Barbara staff members has acquired new skills and tools to help the university thrive. The 16 employees from 11 departments have earned their Lean Six Sigma green belt certifications. The program teaches techniques for improving processes and reducing inefficiencies.

“I’ve been fortunate to work at major companies such as Bank of America, Toyota and Microsoft that apply Six Sigma processes,” said Chief Information Officer Matt Hall. “We can now apply successful corporate practices to higher education, where we face extraordinary pressures to deliver an ever-increasing level of student and research success.”

“The participants in this year’s Lean Six Sigma training represent the talented staff we have at UC Santa Barbara,” added Garry Mac Pherson, vice chancellor for administrative services, who with Hall helped organize the training.

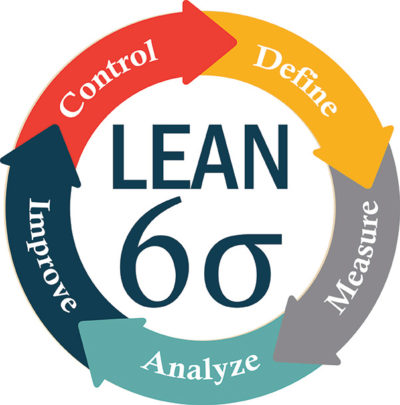

The lean movement began in post-WWII Japan at Toyota as an effort to eliminate waste and maximize output. In the 1980s, Motorola developed the Six Sigma program, which focuses on reducing defects and minimizing process variation. Since then, diverse industries have adopted and combined the complementary approaches, now called Lean Six Sigma. Several organizations offer training in the methodology, and the green belt is the third of five levels of certification.

“What we’re trying to achieve with the Lean Six Sigma green belt course was to bring people from across campus and introduce them to the program’s methodology,” said Matt Erickson, associate director for program management in the office of the CIO, and one of the newly minted greenbelts. “It also gets us to a place where people across the campus have a common language around process improvement.”

The certification involved five days of courses with supplemental online work that took place from December to March. The program culminated in a test and a project that required participants to put the Lean Six Sigma ideas into practice.

One team tackled the task of streamlining the retrieval process for impounded bikes. Pam Gebhardt at the UC Police Department noticed students were becoming increasingly frustrated by the time it took for them to retrieve their bikes from impound.

“The joke was that students would always come in and go, ‘you stole my bike,’” said Gebhardt’s teammate, Policy Coordinator Jennifer Lofthus. “So that became the name of our project.”

Impounding is handled by community service officers (CSOs), students who serve as liaisons between the police department and the student body. The CSOs said they often didn’t fully log incoming bikes, so had to finish this step during the retrieval process, which added time.

The problem seemed obvious, but the Lean Six Sigma mentality requires you to step back and assess the issue methodically to find the root cause, said Lofthus. And when she and Gebhardt looked at the data, they found that most of the CSOs’ time actually went into searching for bikes in the crowded lots, especially when the bikes were over at the Devereux campus.

“It’s a good 20-minute round trip to get there,” Lofthus said. “So we wanted to eliminate the Devereux lot for any bike under 90 days.”

The team found other inefficiencies as well. For instance, they noticed the printer the CSOs used was in another building. Adding a printer next to the desk could shave 3-4 minutes off each retrieval.

In their final report, Gebhardt and Lofthus proposed organizing the impound lots, keeping newly impounded cycles on campus, adding a printer and streamlining the paperwork. Together, they predict these improvements could slash retrieval time by some 35 minutes. The UCPD has already begun implementing these changes, with a goal of finishing the overhaul by the end of May.

It’s easy to jump to conclusions and take reflexive actions when you encounter a problem, Lofthus explained, “but the Lean Six Sigma program forces you to take stock of every single step along the way. It was pretty eye-opening.”